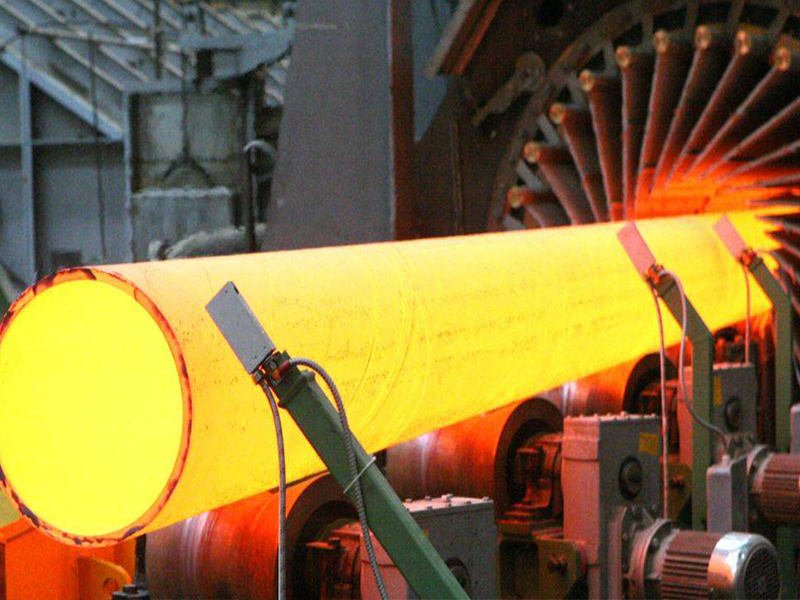

Growth And Development

The Products from Burn Steel Tube are supplied in accordance with appropriate International Standards as well as Customer Specifications in a large variety of steel grades and dimensions. Client specific requirements on execution, tolerances, lengths, mechanical and corrosion properties are offered on request. It ensures high degree of flexibility in production and planning, making possible economical manufacture, especially of small and medium sized production lots. In this manner, our Customers enjoy appreciable economic advantages at an uncompromised level of quality. The company"s unflinching commitment to quality and Customer delight has ensured client loyalty.

Vision

"We aspire to be the global steel industry benchmark for Value Creation and Corporate Citizenship" We make the difference through: